Dismantler style

Re-enactment and documentation of the traditional ‘physical strength based’ informal methodology of dismantling electronic products.

The informal dismantling methodologies exists from decades and is still being used to dismantle more than 70% of global electronic-waste.

Should we eradicate it or learn from it to re-design consumer electronic products?

Act of dismantling :

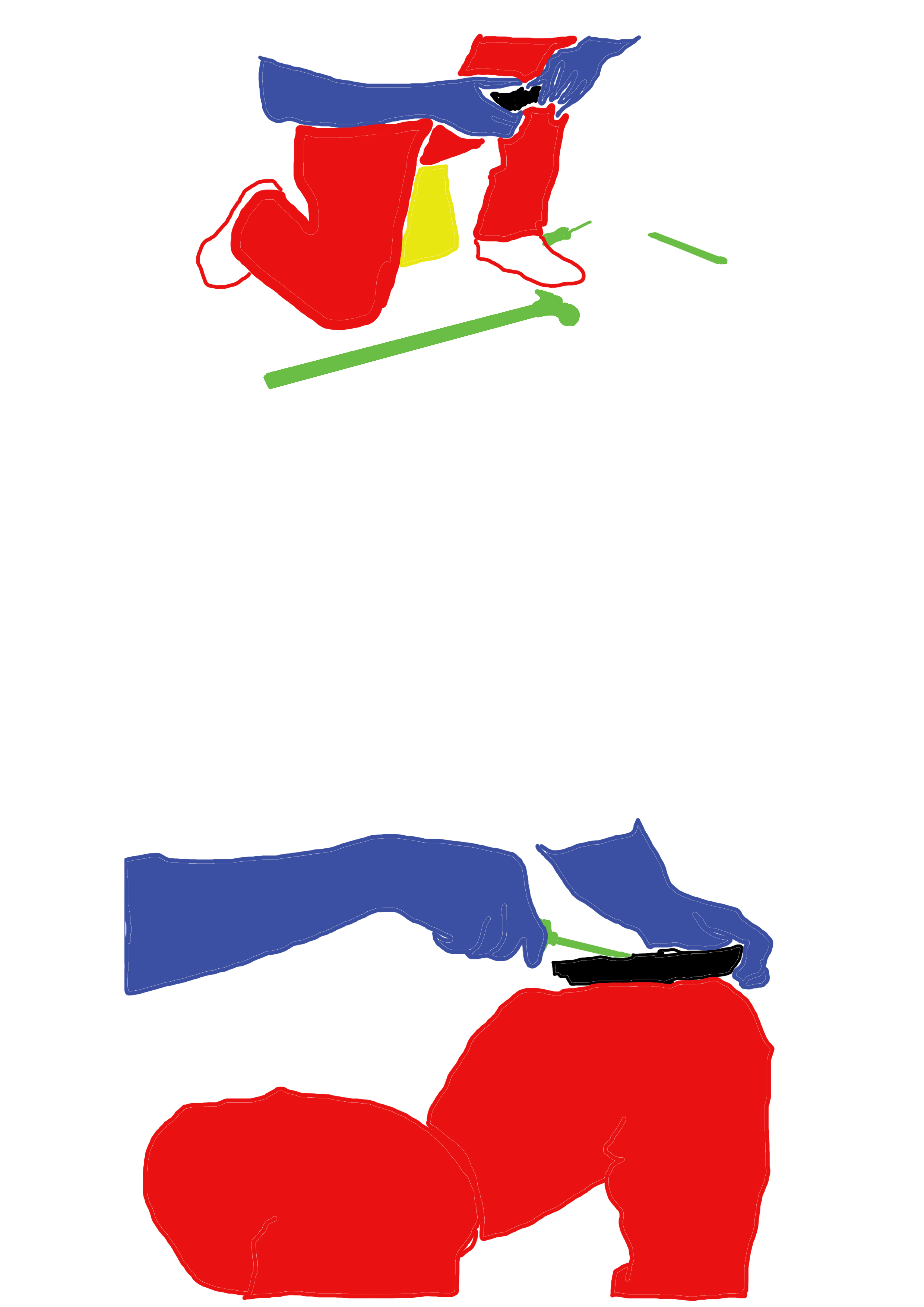

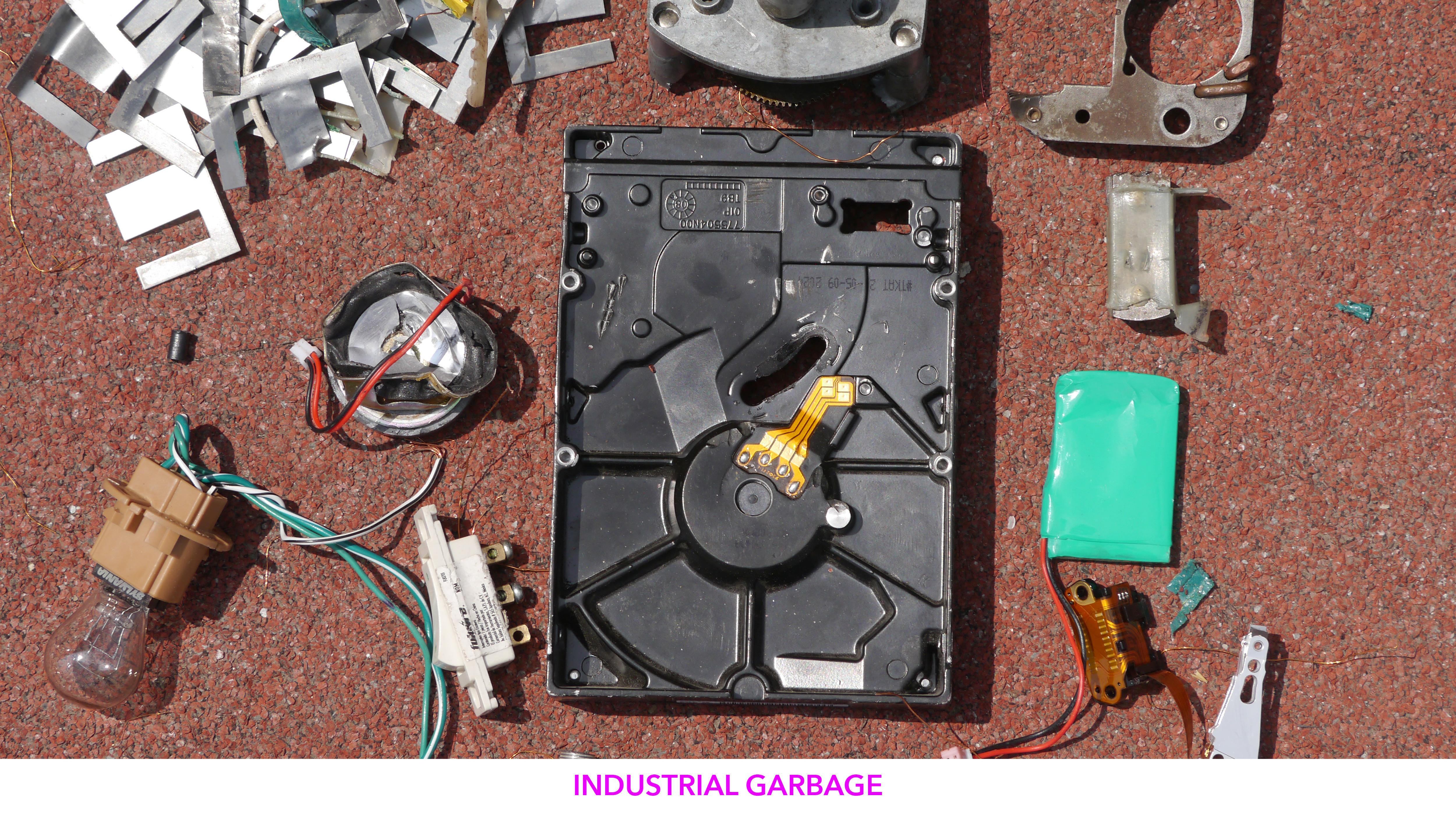

The use of the sheer strength and focus on opening the device combined by fulfilling a certain quota a day drives the worker to break the object faster using any mean and direction. The main motive is to extract copper, PCB, gold, silver, other industrial waste which they can sell further and earn money, the rest is garbage. Nut, bolts, screws, sections, plastic layers are valuable for the manufacturing process but becomes an obstacle for dismantlers

The informal methodologies are common among many informal e-waste recycling sites in the world. It was very important to be humble and learn from it instead of allowing them to exist in a disdained reality. This documentation one of the few recording of informal dismantling.

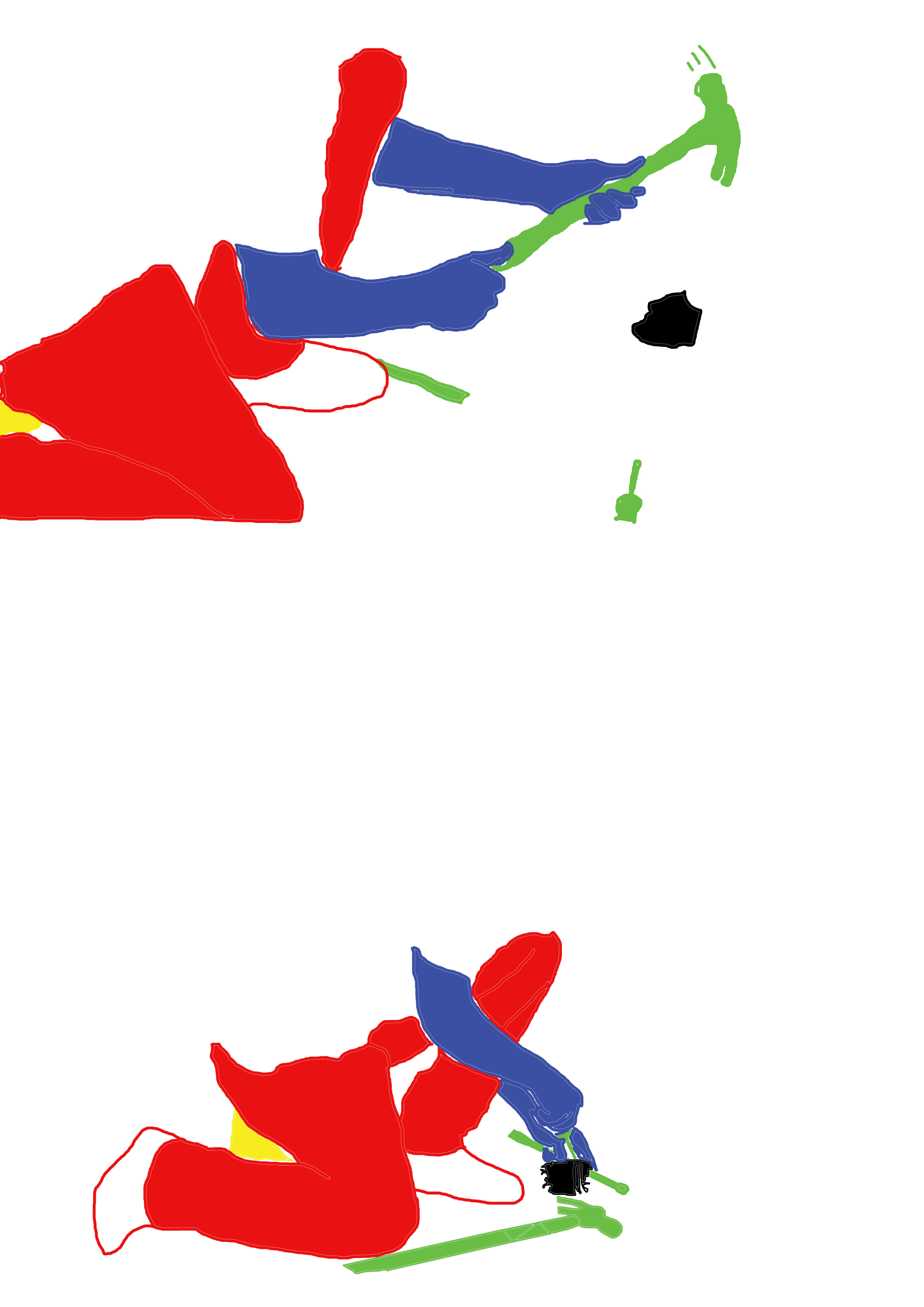

How workers dismantle electronics products only using basic tools and traditional methods?

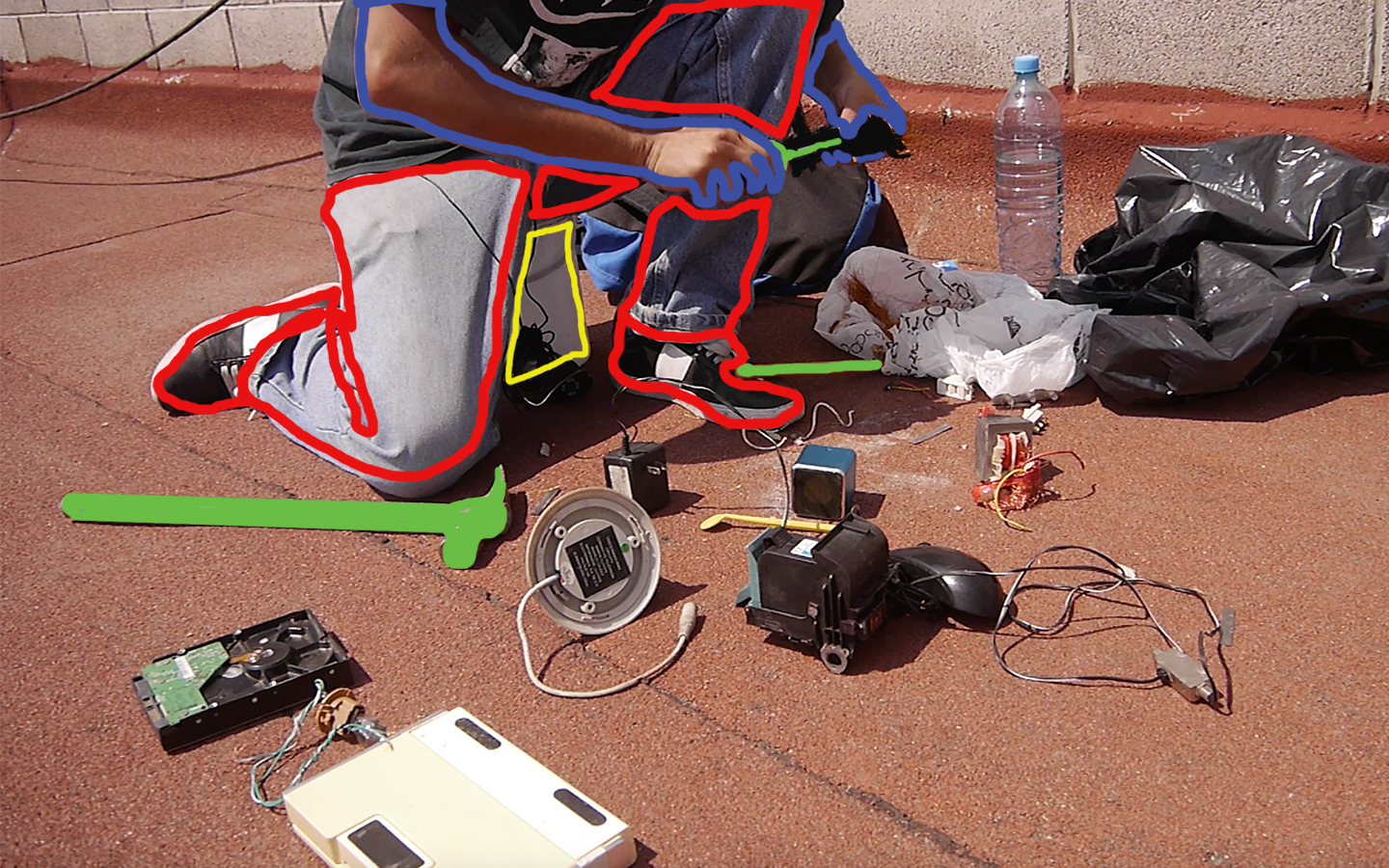

Seating Position

Seating Position

Typically, the work is performed on the streets and sitting on the floor. Individuals and group of people work together while going through different stages of the process like separation, dismantling and collecting. They surround themselves with empty and filled bagsto be used as temporary storage station for items.

They sit low on the ground to be comfortable and work for around 8-9 hours. This is an interesting aspect of how a person adjusts his/her position to break things which allows them to use different part of their body in dismantling activity and at the same time stay comfortable for long period.

They sit low on the ground to be comfortable and work for around 8-9 hours. This is an interesting aspect of how a person adjusts his/her position to break things which allows them to use different part of their body in dismantling activity and at the same time stay comfortable for long period.

Tools

The hammer, chisel and the screwdriver are most common tools workers use. The knee, feet, floor surface, shin and hands also becomes very important part of the breaking process. They adjust in order to make best use of their own selves and the surrounding to break devices.

Workspace

The area around the worker is usually surrounded by bags of things ready to be dismantle and residue after the separation. The re-use of plastic bag as base for the extracted items like copper, iron, etc extracted from different devices is really common. The bags categarises the items to be identitfied and collected later.

END

︎

︎